|

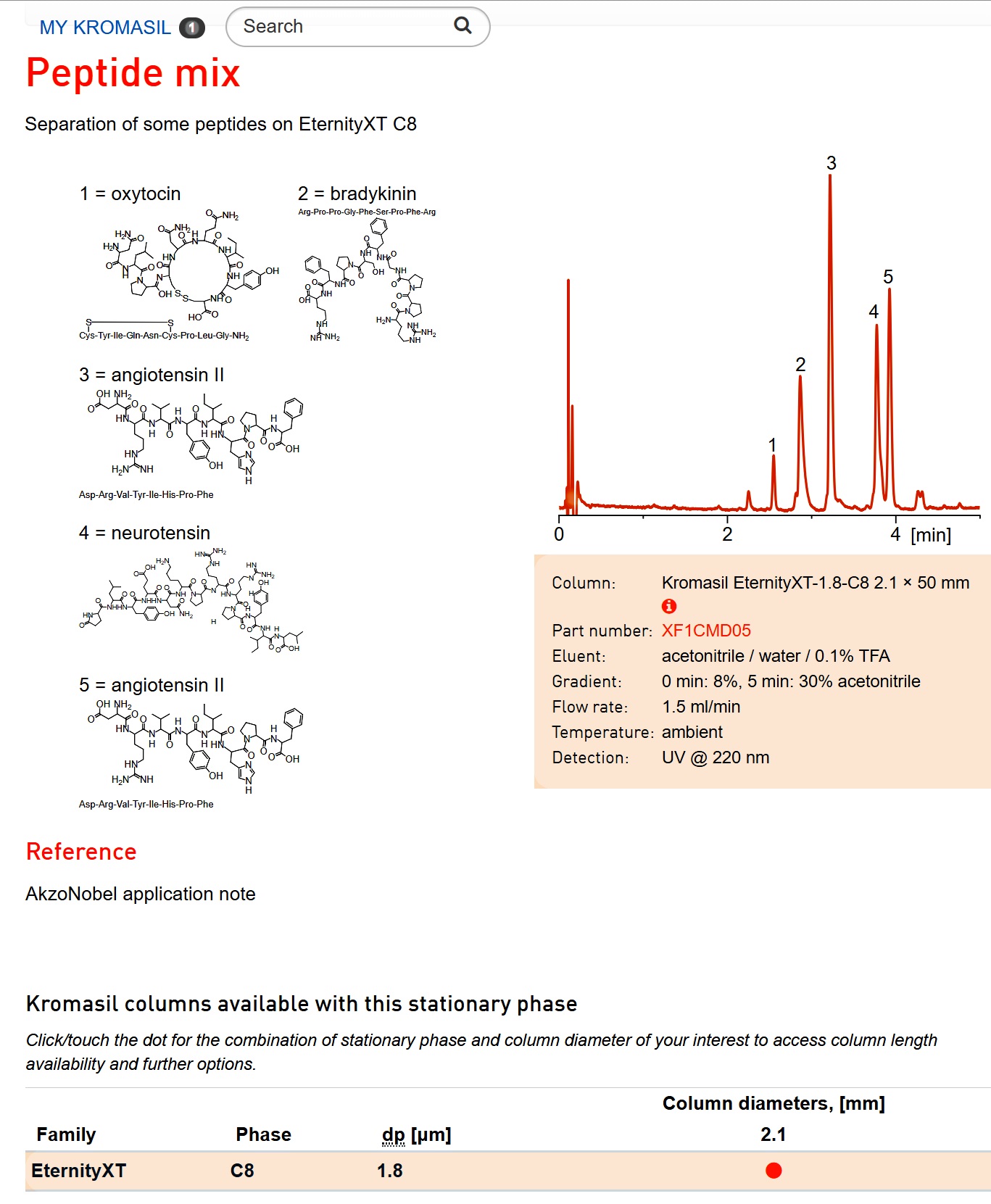

Chromatography Media & Column / C18 / C8 / C4 / Phenyl /

SIL (Silica) / CN (Cyano Propyl Silane) / Diol / HILIC-D

.jpg)

|

C18 (Octadecyl Silane)

C8 (Octyl Silane)

C4 (Butyl Silane)

Phenyl (Phenylpropyl Silane)

SIL (Silica)

CN (Cyano Propyl Silane)

Diol (2-(3-propoxy)ethane-1,2-diol silane)

HILIC-D Diol (conditionized for HILIC)

|

|

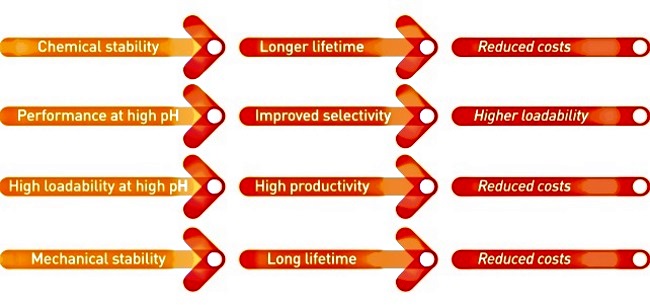

Chemical stability with wide pH window for

improved selectivity, resolution & productivity and the mechanical stability for

withstanding pressure are the key requirements both for the analytical and

preparative chromatography media to realized the longer life and reduce cost

goals.

Kromasil's ultra-high-performance 'spherical chromatography microspheres' are

the world's most pressure resistant, most resistant to acids and bases, the best

porosity, and the best resolution.

The maximum sample load, and other characteristics, become the highest reference

index of global brands.

Https://www.kromasil.com

For regular silica-based stationary phases, exposure to

extreme pH (especially basic) will have a negative impact on the chemical

stability and therefore column lifetime. However, the silica/organosilane

surface of the Kromasil Eternity platform offers a chemical stability that will

secure a long-lasting stationary phase, even under tough pH conditions and

higher temperatures.

The Kromasil Eternity silica matrix.

|

1 - The Bare silica

The Eternity platform is based on the Kromasil 100 Å silica matrix, well known

for high mechanical stability, and a well-defined pore structure.

|

|

2 - Applying the organosilane

layer

The silica matrix is bonded using a patent-pending

technology. An organosilane is immobilized on the silica, and, under certain

proprietary conditions merged into an organic/inorganic interfacial gradient.

|

|

3 - The merged silica/organosilane surface

The pores are virtually returned to their original size,

resulting in a surface exhibiting both organic and inorganic moieties. This

process step has been fine-tuned to give Kromasil EternityXT its extreme

chemical stability, extending the pH range and packing lifetime.

|

|

4 - The derivatized product

Finally the product is functionalized with various

surface chemistries (C18 in illustration), followed by a proprietary endcapping

process.

|

Easy handling of tough demands

|

|

|

|

|

|

|

|

|

|

Kromasil EternityXT builds upon the legacy of the Kromasil Classic silica and

further enhances the performance of preparative chromatography. |

Kromasil Eternity HPLC columns come with particles down to 2.5 μm. EternityXT

extends down to 1.8 μm to fit any UHPLC instrument for better efficiency and

flexibility in the laboratory. |

With the Eternity platform, the boundaries of applicable pH range has moved

beyond what could be expected from the strongest silica matrix. |

Kromasil EternityXT builds upon the legacy of the Kromasil Classic silica and

further enhances the performance of preparative chromatography. |

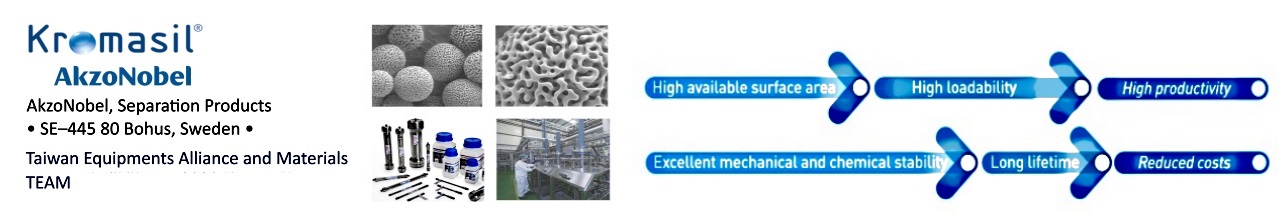

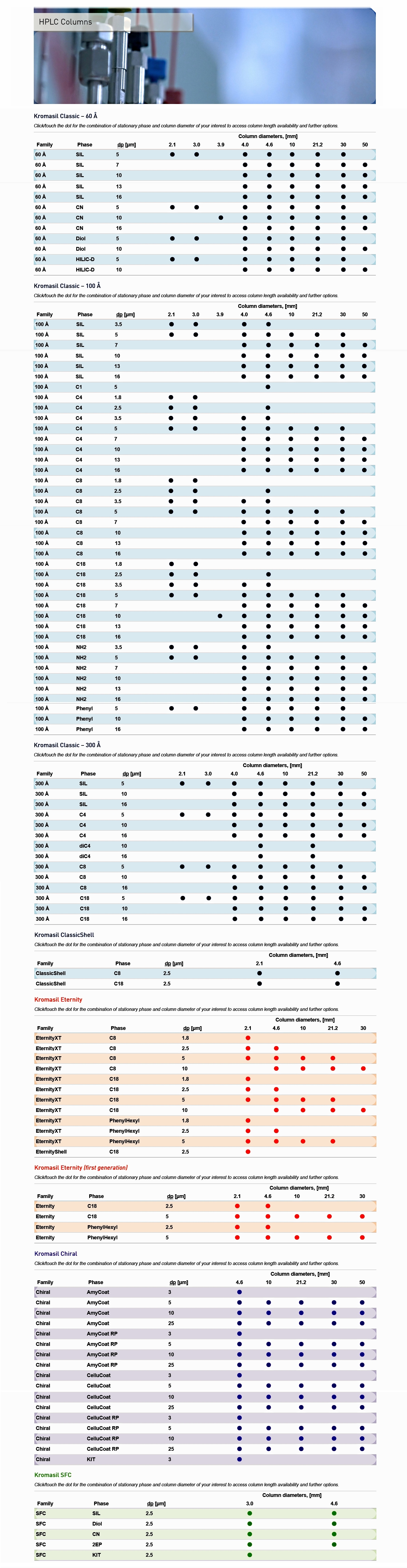

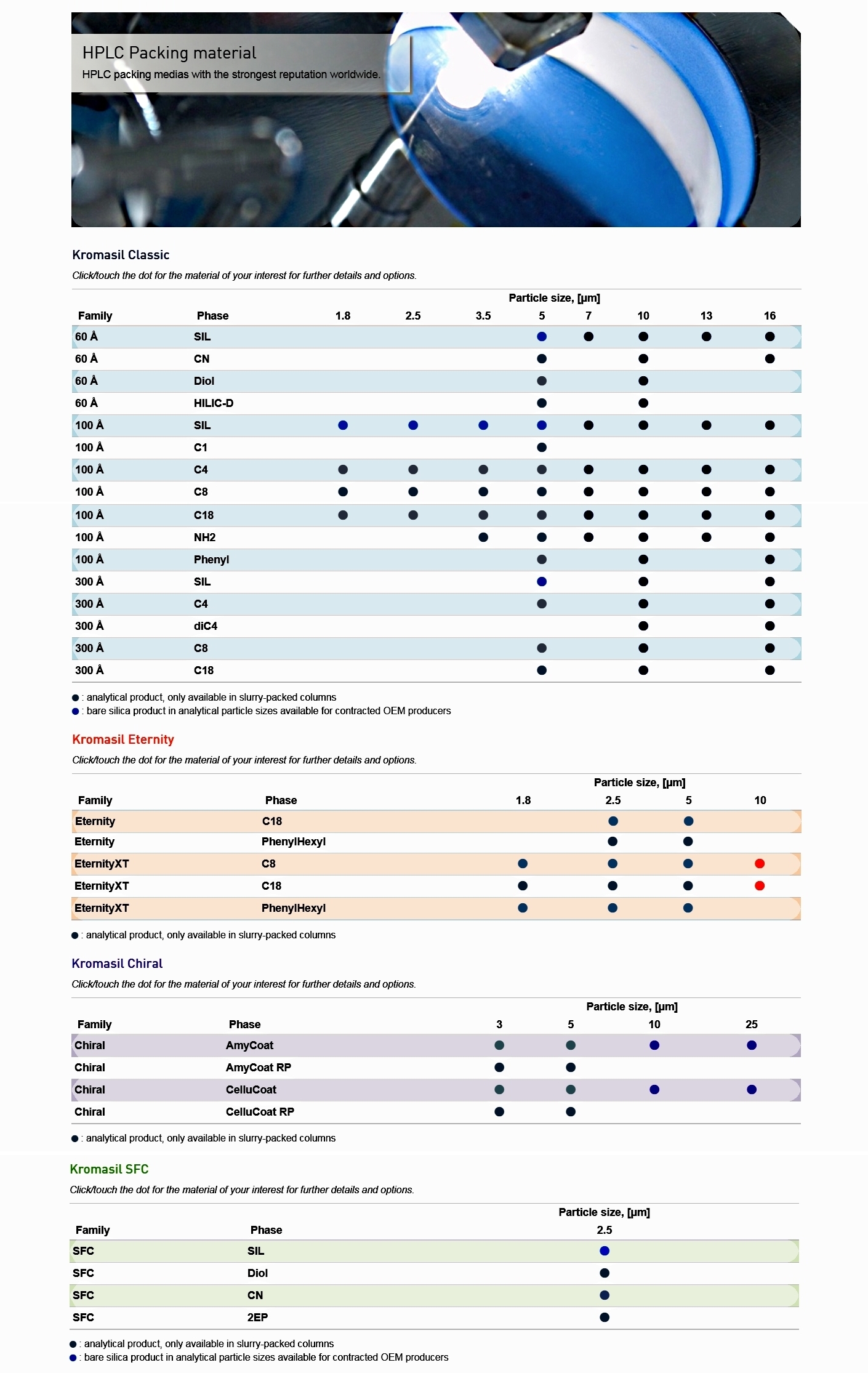

The Kromasil products platforms

Availability of Kromasil UHPLC,

HPLC and SFC columns

https://www.kromasil.com/products/columns/?classic_promoted

Availability of Kromasil HPLC stationary phases in bulk

https://www.kromasil.com/products/bulk/

Application Guide and

Search

A collection of application examples from our labs and users all

over the world that can be browsed and serached by application titles and by

substances using specified Kromasil gel item or any phrases.

General HPLC support

The Kromasil team is always on hand to help you with questions and

problems. With a breadth of experience in separation around the world, our

chemists or chemical engineers can usually pinpoint the problem. Please, do not

hesitate to contact us if you need answers too difficult questions concerning

chromatography. However, we will try to help you right at this moment by giving

you some hints on how to solve common problems

Instructions

|

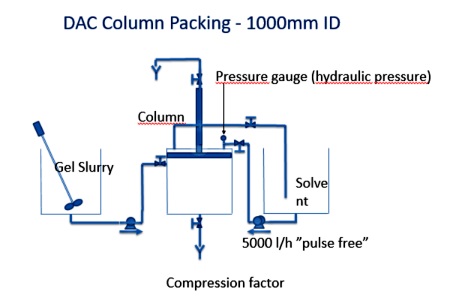

DAC Packing General instructions for packing Kromasil media in Dynamic Axial

Compression (DAC) columns |

|

|

Care and use of Kromasil HPLC columns All Kromasil columns are individually

manufactured and tested to meet strict specification criteria. The following

measures will enhance their performance and lifetime.

|

|

|

Unpacking of Kromasil media Kromasil silica is superior when it comes to

mechanical and chemical stability, and can therefore, under most circumstances,

be reused over and over again. Kromasil can be stored either as a dry powder, or

in a solvent. For storing the silica in a solvent it is recommended that you

unpack and store the used silica in the solvent that you later will use in the

packing process as a slurry solvent. For recommended slurry solvents please see

our packing instructions.

|

|

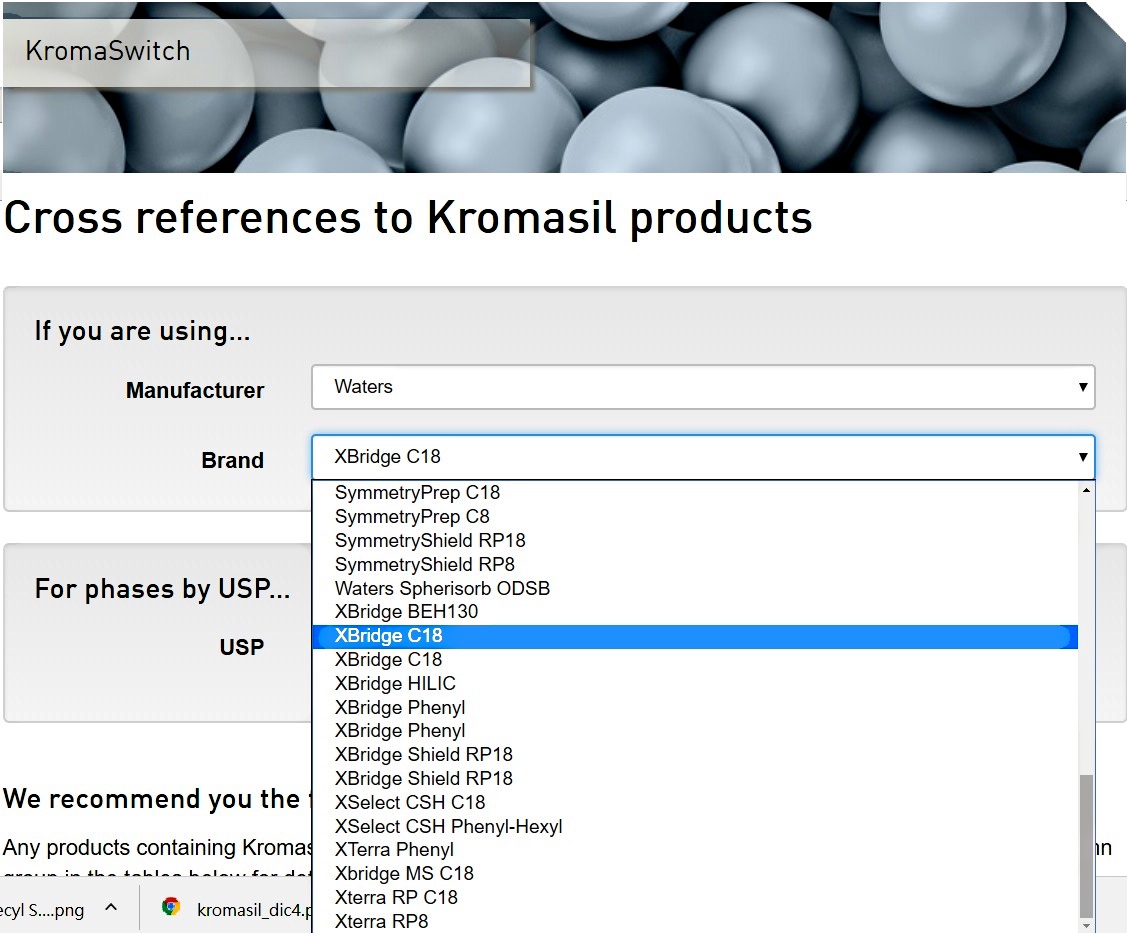

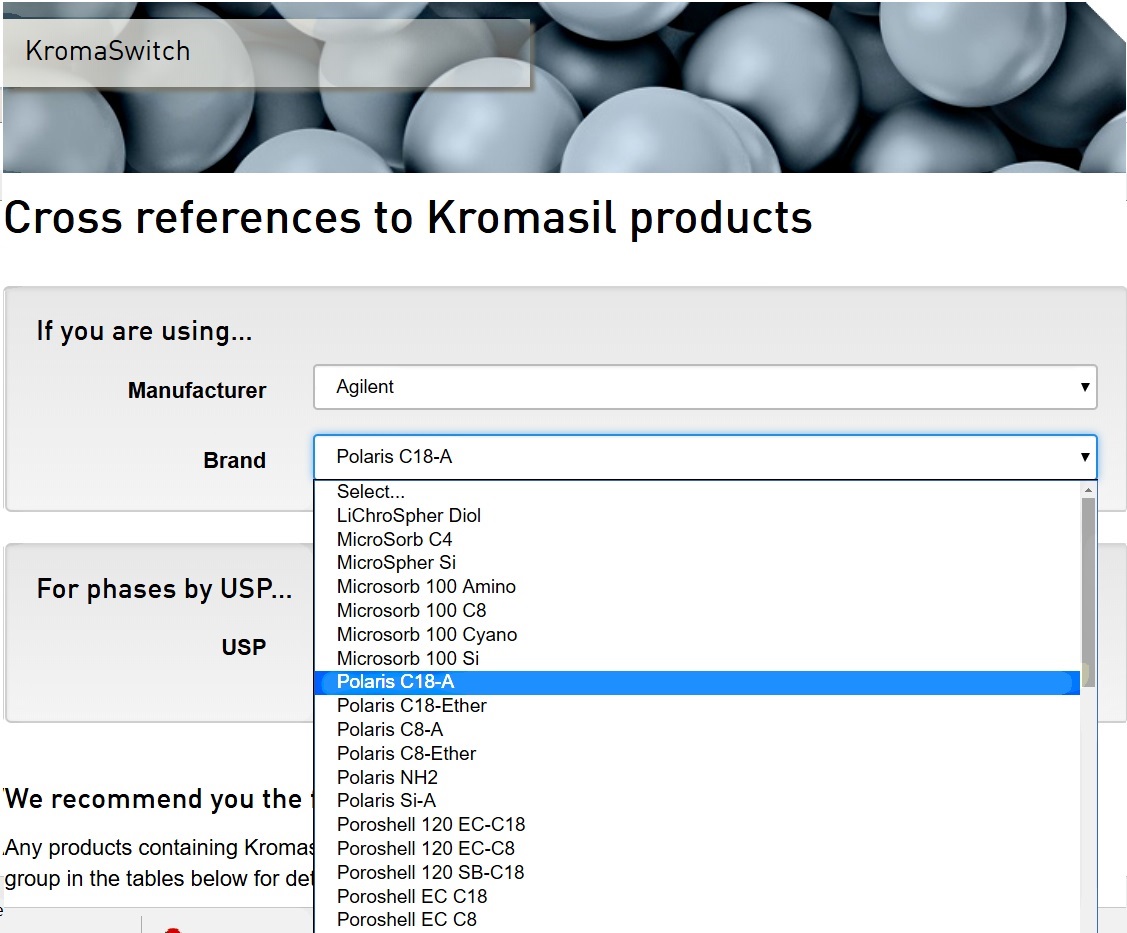

Tools : KromaSwitch - Cross references to Kromasil

products

Kromasil notes

|

Using EternityXT stationary

phase for analysis and purification under reversed-phase chromatography

Silica based chromatography materials are typically considered stable in the

range of pH 2 to pH 8 and separations and purifications are usually carried out

under these conditions. However, there are applications where higher pH could be

used to achieve better purifications to attain higher purity and/or yield.

EternityXT stationary phase materials are ideal for production facilities that

need to work with an extended range of pH because it is stable under low and

high pH conditions. |

|

On the purification of 100’s

potential API candidates by reversed-phase preparative chromatography

UCB is a global biopharmaceutical company dedicated to the research, development

and commercialization of innovative medicines with a focus on the fields of

central nervous system disorders and immunology disorders. At UCB Biopharma in

Braine-l’Alleud (Belgium), one of the two research centers, day after day,

numerous intermediates and potential Active Pharmaceutical Ingredient (API)

candidates are sent to the Preparative Chromatography Team for purification. |

|

Improved loadability for

basic APIs - run at high pH

The main proportion of all synthetic pharmaceutical APIs are basic in nature,

and will in many cases exhibit an increased loadability, and hence productivity,

at high pH. Basic peptides, oligos, PNAs, etc, will also benefit from high pH

separation methods. |

|

A brief history of

preparative liquid chromatography

Traditional preparative liquid chromatography was born in 1903 when the Russian

botanist M. Twsett made the first separation of carotene pigments. The columns

he used were made of glass, they were packed with gravels and were basically

operated at atmospheric pressure. This situation kept unchanged for many years,

until the 1960’s when organic chemists began to use stainless steel columns

operated at a few bars. |

|

Separation of fish oil esters

EPA and DHA on Kromasil C18

A nice scale-up example from column i.d. 4.6 to 21.2 mm. |

|

Of pH and adsorption

isotherms

In the last issue of KromaNews we looked at the importance of performing

overloading studies during preparative HPLC method development. It was shown

that switching the stationary phase, while keeping all other chromatographic

parameters constant, altered the non-linear adsorption behavior. In this issue,

the adsorption behavior of a peptide on the stationary phase at different buffer

pH will be shown. |

|

The art of packing DAC

columns – some hints and advice

In order to have a seamless and problem-free scale-up, and to be able to

establish an efficient and cost-effective production, one must assure that the

large scale column used is packed with the same high efficiency as the column

used for the method development. And this can relatively easy be done with

today´s DAC columns available on the market! |

|

The importance of overloading

studies in method development – a case study

Preparative HPLC differs from analytical HPLC since it needs to be performed in

the nonlinear part of the adsorption isotherm in order to maximize important

parameters such as column loading and productivity. In preparative HPLC, method

development screening is commonly performed with analytical injections. This

makes it possible to establish and compare selectivity in different

chromatographic systems. From the screening, one or more candidate phases are

selected for a closer preparative study with overloaded injections. This case

study illustrates the risk of relying only on selectivity during preparative

method development. The scope of the study was to separate an API (Mw ≈ 900

g/mol) from its impurities and achieve 99.0% purity with as high productivity as

possible |

|

Kromasil preparative HPLC

applications – success stories 2. Purification of orlistat

Obesity has developed into a severe, global health problem during the last

decades, and as a result pharmaceutical companies have tried to develop a remedy

for obesity, that can be used in combination with dieting and physical exercise.

The one medication currently available and approved for long-term use is an

anti-obesity drug marketed as Xenical or Alli. The API in the drug is Orlistat,

also known as tetrahydrolipstatin. |

|

Pharmaceutical company uses

Kromasil's method development expertise to improve productivity in its

purification process

In recent years, India has proven to be an area of strong growth in the peptide

market. Numerous Indian companies are developing biosimilars while several

others are focusing on research and development (R&D) of novel therapeutic

peptides. Issar Pharmaceuticals, located in the Hyderabad, India is an example

of a company that has specialized in providing novel therapeutic peptides. The

company has successfully synthesized a number of promising peptides in its

pipeline, most notably being the Melgain®, which was commercialized in 2004. |

|

Scaling methodology in

preparative batch HPLC

One of the beauties of purification using preparative HPLC is the simplicity of

how scaling of a separation rocess is made. This article will give you an

insight into how this is done, and which difficulties may occur. |

|

Kromasil preparative HPLC

applications – success stories 1. Purification of insulin

Kromasil packing media are today the dominating materials used for large-scale

production of human insulin and variants, among many other applications.

Multi-ton volumes of Kromasil per year are used globally to produce these APIs,

with high purity demands. This article will show an example of the development

work that has been performed to facilitate cost-effective processes for the

final purification of human insulin, and to service our customers in order to

lower their costs. |

|

HPLC, a rapid development and

a robust production process to purify APIs

With over 25 years of expertise in the development of preparative chromatography

equipment and purification processes, Novasep has pioneered the field of

industrial HPLC including both batch and continuous (SMB) technologies. Within

recently extended facilities in Shanghai, the company offers process development

and scale-up services for the production of APIs under cGMP conditions. |

|

Why you can't have your cake

and eat it too

In order to develop a successful preparative HPLC method one first needs to

define relevant goals for the specific purification. The most important and

common parameters defining the quality of a separation is loading (defined as

mcrude/mresin), purity and yield. Purity is usually already defined by

regulatory agencies (such as FDA or equivalent) and often includes area

percentage of product as well as individual impurities, while yield simply is

the ratio of purified product divided by amount loaded onto the column. |

|

The importance of a

chemically stable HPLC packing material

In preparative chromatography it is of uttermost importance that all parameters

are optimized to give the lowest possible cost for the target substance

purified. We have in previous articles described the importance of optimization

of the HPLC separation. However, another factor that could greatly influence

your separation cost is the lifetime of the packing material. To run the

separation using a stable packing material will not only result in a lower cost

due to a longer lifetime of the packing material, but the separation can also be

run with less disturbances, with more stable conditions for a long time.

|

|

Outsourced production – an

opportunity for CMOs

Major changes are occurring in the development of new therapeutics within large

pharmaceutical and biotechnology companies. These companies are becoming leaner

and rely more on outsourcing, anything from analytical methods to full-scale

contract production. With the change in paradigm there is a need for contract

manufacturers (CMOs) to expand their services and guarantee quality work.

Experience allows for contract manufacturing companies to deliver anything from

robust analytical methods to purified APIs at a reasonable cost. |

|

Gradient or isocratic elution

in preparative reversed phase HPLC

A common question that often arises in the discussion between prep

chromatographers is when and why one should choose either isocratic or gradient

elution? Since we in the Kromasil group have a long experience of developing

large scale separations we would like to share some of these experiences with

the readers of KromaNews. |

|

Basic methodology for method

development in preparative HPLC

Quite often one meets people with excellent knowledge and experience in

analytical HPLC, and while much theory and underlying equations can be used on a

preparative scale, a lot may differ. The main difference is the scope of the

separation. In analytical chromatography you are most certainly looking for

information in some way, either identification or quantification (or both) of

one or several peaks in one chromatogram. However, in preparative chromatography

the isolation of a single substance at a certain purity is usually the main

goal. This difference has a large impact on how to develop the chromatographic

method in order to optimize factors such as yield, purity and loadability. |

|

Recent changes: the former

and the new General Manager

During the last one and a half years Separation Products has undergone some

important changes, as Domingo Sanchez, one of the founders of the group, has

retired as General Manager. Domingo is now replaced by Sylvia Winkel Pettersson,

who has been working in the Kromasil group since 1999 in different positions.

Sylvia hence has a strong background and experiences to support her as

Separation Products' new General Manager.. |

|

Buffer Capacity – an

underestimated parameter in prep RP-HPLC

.. |

|

Optimization in Prep HPLC

The recent years has seen a tremendous increase in the use of Industrial Scale

HPLC, especially in emerging countries like India and China. Many large DAC

columns have been installed, and are run using short bed lengths, together with

small, spherical, silica-based particles, and relatively high flow rates. This

is what we call the High Performance Concept in preparative HPLC. |

|

Exploring the limits in

Brazil

Separation Products has had a long collaboration with the group of Professor

Cesar Santana at the Universidade Estadual de Campinas in Brazil. Professor

Santana and his group have produced several scientific papers in the field of

large scale purification of enantiomers. We are now proud to give the readers of

KromaNews a flavor of the work of Professor Santana's group and some nice

pictures from the lovely group in Brazil. |

|

Give a little, gain a lot

Kromasil offers the lowest possible total separation cost by providing the best

silica-based HPLC, SMB and SFC packing material. Superior loadability and

lifetime let you boost productivity and reduce costs. |

|

Excluding additives in chiral

preparative separations

Mobile phase additives are commonly used in analytical chiral separations

without trouble. But in preparative scale, additives make solvent recycling

tricky and can cause re-racemization. By using Kromasil AmyCoat or CelluCoat it

is possible to exclude additives in chiral preparative separations. |

Publication details : Kromasil Guide

Our brands - AkzoNobel

|